What exactly is vegan leather? Get to know all about mushroom leather, mycelium and other bio-based monomers

Animal leather is one of the most ancient materials used by humans and was considered a social status symbol for a long time. However, nowadays this material is no longer in line with the times. There has been a significant change in public opinion in relation to the production of traditional leather. This is due to a growing awareness of the cruelty of factory farming, the social conditions for workers during leather production and the environmental impact of tanning. Consumers are increasingly looking for alternatives, making it necessary for the fashion industry to rethink its approach.

As a result, material innovations that can replace animal leather are increasingly conquering the market. From small independent brands to luxury brands like Gucci and sportswear manufacturers like Adidas, fashion companies are launching a growing number of products made from non-animal leather, following in the footsteps of Stella McCartney, who has been using vegan leather since she founded her label in 2001. According to Infinium Global Research's February 2021 market report, the global vegan leather market is expected to reach a compound annual growth rate (CAGR) of 48,1 percent over the forecast period from 2020 to 2026.

With the variety of new materials entering the market every year, it is difficult to keep track of them all. In addition, reporting on the various synthetic and so-called plant-based alternatives is often inaccurate, misleading or simply greenwashing. Not every non-animal leather is also a vegan leather, as materials from animals – such as glue and dye – may also be used in the production process. Neither does every vegan leather have the same properties and environmental impact, as the production methods are quite different.

As a manufactory and brand that specializes in vegan and biobased materials, we are actively involved in material developments with many innovators and rigorously test new innovations. The following article therefore aims to create order, to disentangle the prevailing confusion of definitions and to give an overview of the different types of leather. In Part 1 of our Vegan Leather Guide, we will first examine mono-materials (also called monomers), which include animal leather and new material developments made from mycelium, bacterial nanocellulose or collagen.

Apple leather? Pineapple leather? But what does that mean? Learn more about coated materials next week in part 2 of our Vegan Leather Guide. At the very end of the article you will also find an overview table with the most important characteristics of well-known vegan leathers.

Production: Before we take a closer look at the various vegan leathers, let's briefly return to the original product: Animal leather is still referred to as a natural product in articles and vegan leather is praised for its ethical superiority, but criticized in terms of sustainability.

Animal leather is made from the skins of animals. The skin of the animals (usually cows, goats or sheep, but also exotic animals like crocodiles and snakes) is first preserved, then soaked to clean and rehydrated. After that, components such as hair or flesh are removed. Next, the animal skin is dehydrated, pickled and degreased. In a complex process, the hide is then tanned, further processed and later usually dyed or coated. After about 20-40 process steps, the result is a robust, relatively flexible and water- and dirt-repellent material.

Performance:The final product thus in fact has relatively little to do with the natural animal skin. Instead, each of these steps is designed to keep a biological material from decomposing and to make it last as long as possible. In addition, animal leather is often, if not mostly, coated with polyurethane or other synthetic materials to even out imperfections in the structure and make it more durable against moisture and humidity. Take a closer look at the leather when shopping: if the graining is identical and uniform at all parts of the product, it may well be that the material is coated. A coating up to 0.15 mm is not subject to declaration, so the material may still be called leather.

More than 70% of animal skins are processed in developing countries, where the lack of wastewater systems means that toxic waste could end up in the groundwater.

Sustainability:Animal leather also scores poorly in terms of environmental impact: The hides must be tanned before they can be used in leather goods, as they would otherwise decompose and become unusable for further processing. The most used tanning agent is chromium, which can transform to toxic chromium IV (a carconigen) if not processed properly. In the EU there are strict regulations on how much chromium IV is allowed to be detected in the end-product, but government investigations found that these threshold values are often exceeded. Besides chromium, other chemical auxiliaries are used, with studies showing that for 1 kg of leather, ca. 2.5 kg of chemicals are needed. Those synthetic materials can also be classified as problematic for human and environmental toxicity. The manufacturing process consumes an enormous amount of water and causes high CO2 emissions. This results in environmentally harmful, non-biodegradable waste products , such as tannin-containing wastewater or chemical containing solid wastes like raw hides or flesh. Moreover, more than 70% of animal skins are processed in developing countries, where the lack of wastewater systems means that toxic waste ends up in the groundwater and harms people working in tanneries. Vegetable tanning can offer advantages compared to chromium in regards to toxicity and biodegradability. They need more water and energy during processing and can only be used for specific types and colors of leather. Their application is therefore still very limited and vegetable tanning agents are mostly combined with synthetics to reduce cost and increase performance of the resulting leather.

Disposal:Biodegradation of most animal leather is also severely limited after use, and recycling is not technologically feasible or economically viable. So animal leather is currently either landfilled or incinerated.

Inputs and Outputs of Producing 1 kg of leather (© Melina Bucher)

Read more about animal leather in our detailed article The 5 most popular myths about animal leather.

There are some companies developing materials that mimic animal skin as a raw material in the leather process. These materials can then be made durable and adapted in their physical properties by either mechanical or chemical processes. Cellulose-containing materials, collagen or fungal biomass are used for this purpose. The main goal is to replace animal or synthetic raw materials with biological ones. In the following, we present some of these innovations in more detail.

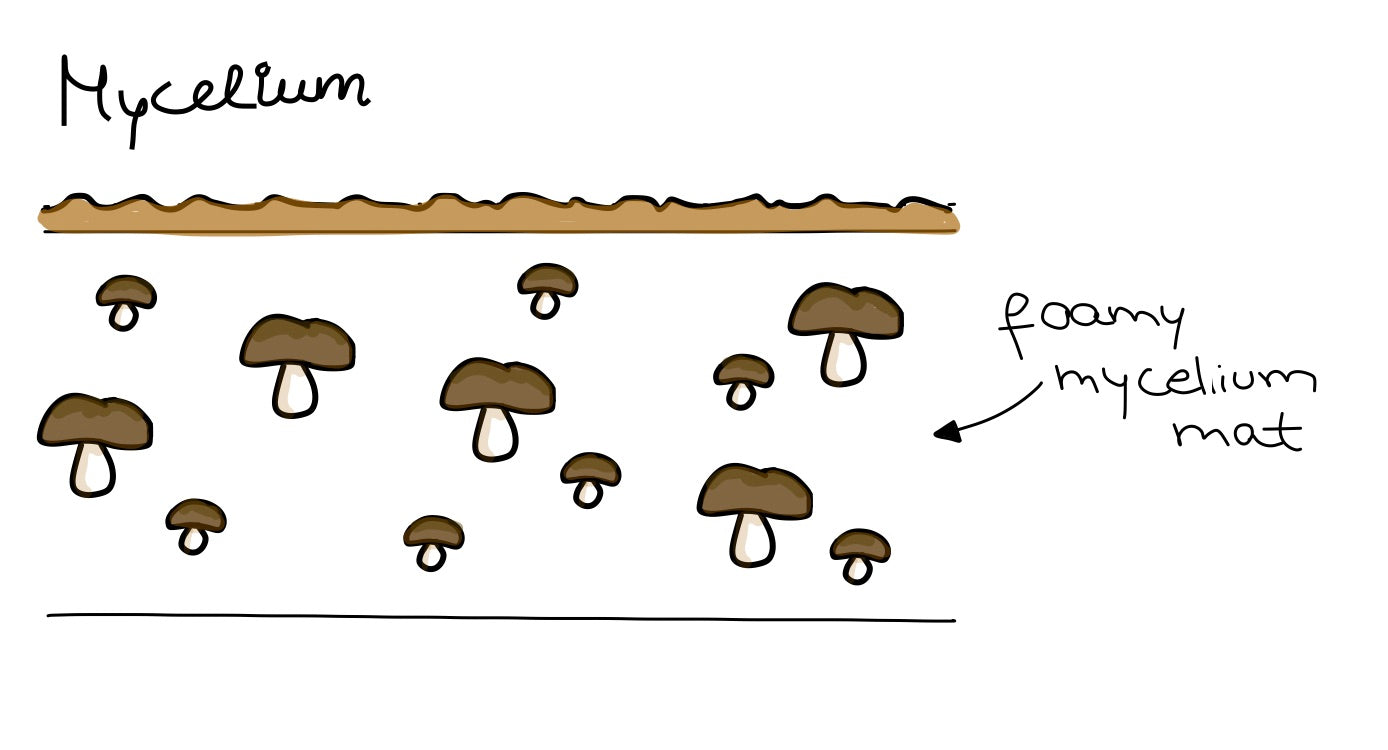

Production:In the making of mushroom leather from mycelium, mushroom cells are grown into mycelium, a net-like biological mass. Mycelia are structures of the fungus that usually grow underground and are therefore less well known than the superficial fungal body. There are several material innovators working on mycelium-based materials that employ slightly different production techniques. The mycelium usually grows on agricultural by-products and produces a foam-like mat that can then be processed in chemical and mechanical processes to produce a leather-like material. Some innovators also test approaches to let the mycelium eat cotton or other textile materials to increase strength of the material.

Cross-Section of Mycelium Leather (© Melina Bucher)

Performance: MycoWorks, which manufactures mycelium leather marketed under the product name Reishi, has commissioned extensive testing of material strength, durability and color fastness. The results show that the mycelium leather has similar properties to animal leather. The Reishi High Strength material even outperforms animal leather – but in this case, a polyester carrier and coating were applied. Bolt Threads used a synthetic coating for a faster go-to-market approach. Overall, the right processing technique, the combination with a textile backer or a coating enhance the overall performance of mycelium materials.

Sustainability:The companies MycoWorks and Bolt Threads use sawdust, a waste product from forestry, to grow mycelium. Thereby, the foam-like mats can be produced in 4-9 days. Since the mycelium grows in a naturally biological process and does not require light to grow, the environmental impact should be correspondingly low. Mushrooms absorb and store CO2 as they grow, so the process is CO2-neutral. The subsequent processing of the mats into leather consumes resources – which depend on the selected processes of the manufacturer. Bolt Threads, for example, worked with leather tanneries that have to meet special requirements in terms of sustainability. However, more in-depth information is not publicly available.

Disposal: Mycelium is a natural, biodegradable material. In order to determine the biodegradability or recyclability of the end-product, it is necessary to consider the chemicals involved in the production processes or, if applicable, the dyes and coatings selected. This is another area where information is still lacking.

Deployment in the fashion industry: Bolt Threads, the company developing the material Mylo, has raised approximately USD 471 million in 7 investment rounds. They worked in a consortium with Adidas, Kering, Lululemon and Stella McCartney to develop products for different applications. At Paris Fashion Week, Stella McCartney showed a handbag made of Mylo on the runway for the first time in 2021 and thereafter launched a limited edition of 100 Frayme bags. In 2023, after not securing additional investment, Mylo production was stopped and Bolt Threads combined its business with Golden Arrow Merger Cop. If and when the material will be sold again is still not known. The company MycoWorks, which markets its mushroom leather under the name Reishi, has secured funding of USD 125 million in a series C round in 2022. Investors include automotive company General Motors and celebrities Natalie portman. They have a long term strategic partnership with Hèrmes, although the handbag that was shown was never available for sale and still contains trims made from animal leather. They have launched some capsule collection with artists like Nick Fouquet, and Daniel Martin Made. Currently, material availability is scarce. In 2023 they started building a new production facility which has the potential to increase availability in the upcoming years. The Italian company Sqim, formerly known as Mogu, announced a raise of EUR 11 million in its series A round in January 2024. They made headlines with their Paris Fashion Week runway debut in 2022, when Balenciaga used their Material Ephea for a floor-length coat.

Mycelium Foam Mats (left) and finished Mylo (right) (© Bolt Threads)

Production: Muskin is a leather made from the caps of the Phellinus ellip-soideus. After extraction, the caps are cut into thin slices before being treated in chemical and mechanical processes similar to those used for animal leather. However, the leather can currently only be produced in small quantities, so it is not very suitable for industrial purposes.

Cross-Section of MuSkin Mushroom Leather (© Melina Bucher)

Performance: Muskin leather offers special properties such as antibacterial action and moisture management. Although the manufacturer states that the material does not have the mechanical properties of animal leather. However, it can be combined with carrier materials or waxes to improve the performance.

Sustainability: The fungus used to make Muskin is harvested from nature. According to the manufacturer, the material is treated without toxic substances and is plastic-free. Further information on the environmental impact of the manufacturing process has not been ascertainable.

Disposal: Since the material is completely natural in origin, it should be biologically degradable. However, this may change depending on whether and how it is bonded to textile backers or which waxes and dyes are used.

Deployment in the fashion industry: MuSkin is manufactured in Italy by Grado Zero Innovation. At the moment, production is only possible in small quantities of 40-50 pieces per month, which is why it is not suitable for industrial purposes, but for special one-off pieces. Besides, it is not produced in running meters, but only in individual pieces – so one is dependent on the size of the mushroom, similar to the hide size for animal leather.

MuSkin Vegan Mushroom Leather (© Life Materials)

Production:Materials made with bacteria? What may sound gross at first, actually leads to completely natural and beautiful materials. The company Polybion creates their biomaterial material Celium by feeding bacteria with fruit waste in bioreactors. The bacteria then create cellulose (the building block of plants) as a metabolic by-product in 7-25 days depending on the desired thickness. The cellulose membrane is then stabilized in a tanning-like process without using chromium but using significantly less water and energy. Modern Synthesis also feeds bacteria to agricultural waste. Their unique approach is to feed the bacteria in a framework of thread to create a more textile like material. This leads to a nonwoven hybrid material that is a mesh of a leather like drape, a textile like look and a dry and warm touch like paper.

Performance:Polybion has commissioned extensive testing of material strength, durability and color fastness. The results show promising performance metrics. The company says that the material can be tuned to the specific performance parameters by using different bacteria, tanning and dyes. As there are currently no products available on the market, further investigation is needed to evaluate the performance. Modern Synthesis says their unique material is incredibly strong and lightweight. Depending on the textile structure used, the haptic and performance can be tuned.

Sustainability:Polybion uses local fruit waste to feed their bacteria and their whole production is concentrated in a 30 km radius in Mexico. Energy used is coming from photovoltaics. The subsequent processing of the bacterial cellulose into a leather-like material is done similarly to leather with tanning and dyeing. The company claims to use green chemistry compliant with EPA, REACH and ZDHC regulation. The material is said to be produced in a circular loop system, without further explaining the chemicals used in the process. In a preliminary LCA type impact assessment study, the calculated environmental impact was 5 times lower than the one from animal leather above impact categories. Modern Synthesis also feeds bacteria to agricultural waste. They incorporate other natural ingredients in their proprietary formulation and use green chemistry to make their material durable, that are not further specified. They claim that the material only uses a fraction of carbon emissions, water and land without providing any specific sources.

Disposal:The raw material is made from bacterial cellulose which is biodegradable. To evaluate the overall biodegradability of the end-product Celium, a closer look at the process chemicals and dyes is needed. Polybion states that the material will be circular, which would be very exciting! Modern Synthesis claim the end-product to be completely biobased and petrochemical free in the undyed version.

Deployment in the fashion industry:Polybion is still under development and has no commercially available products made from their material on the market. They have created a very cool green and yellow jacket together with Ganni that was showcased at the Global Fashion Summit in 2023. They built their company around scalability though and say they will be able to produce 1.1 million sqft. per year. Modern Synthesis closed a USD 4.1 million seed round in 2022 and is currently still in lab scale. In 2023, they showcased the Bou Bag in collaboration with Ganni with a planned commercial launch in 2025.

Companies like Modern Meadow, a biotech startup from the U.S., follow a different path: They develop collagen - the basic building block of animal skin - directly in the laboratory. In the early stages of development, skin cells were cultivated in the lab for this purpose. In the meantime, a specific yeast strain is fed with sugar in a fermentation process, which directly produces protein.

The benefit: Whereas traditional leather production processes are designed to remove all substances that do not consist of collagen from the animal skin, Modern Meadow produces the collagen directly. The raw material can then be used in the same way known for cow hides in the leather industry – which is why it is possible to revert to previous processing techniques – only without animals. Today, their Bio-Alloy consisting of their proprietary protein and biopolymer is used in materials as a coating or together with synthetics, which makes the material not 100% bio-based. Pact, formerly known as Hide Biotech, is also using collagen as a building block. However, after they announced last year to develop vegan materials with cow collagen, they now switched plans and use collagen from fish farming, which makes the material not animal friendly.

Along with the mono-materials discussed in more detail in this article, there are a variety of coated materials that are used instead of animal leather. These are materials that consist of a carrier such as cotton and one or more coatings. You can find all the information about materials such as apple leather, cactus leather or pineapple leather in our second part of the Vegan Leather Guide.

In the following you can find a thorough comparison of the most talked about vegan leathers based on scientific research. Where scientific research is not yet available, we marked as no sufficient data available. For the evaluation of performance, we included company information as well as our own experiences with the materials.

Comparison of the most talked about vegan leathers (© Melina Bucher)