What exactly is vegan leather? Get to know all about apple leather, cactus leather, pineapple leather and co.

The market for leather products is in upheaval - innovations that attempt to replace fossil-based polymers with biogenic and fully biodegradable materials are especially in demand. A large number of established companies, but especially startups, are developing these new innovative materials. New terms like vegan leather, plant-based or bio-based arouse to differentiate oneself from the typical synthetic faux leather, also leading to a confusion about the actual content of the different materials.

So what do those terms actually mean? Are pineapple leather, apple leather and cactus leather really as sustainable as the name suggests? As we have taken a closer look at animal leather and vegan mono-materials in the Vegan Leather Guide Part 1, in this article we will provide you with information about the different types of coated materials. At the very end of the article you will also find an overview table with the key features of the most popular material innovations and their technologies.

Technology: Synthetic leather usually consists of a textile carrier coated with two or more synthetic polymer layers. The carrier materials used are, for instance, polyester, recycled polyester or cotton, which are coated with polyvinyl chloride (PVC, vinyl) or polyurethane (PU). The leather-like surface appearance is imitated by the embossing of a grain structure [1]. Attention: Not every synthetic leather is also automatically vegan – it depends on the colors, adhesives and other raw materials used in the process.

Source: own illustration. [2]

Performance: Synthetic leather - also known as faux leather, PU leather or artificial leather - is often associated with poor quality. This reputation is mainly due to cheaply produced imitation leather variants of fast fashion companies. However, man-made synthetic leather is almost unrestricted in terms of its quality and properties.

The quality depends on the raw materials used (base material, coating) as well as the processing. Moreover, unlike its animal counterpart, the properties such as water resistance, flexibility and durability can be modified flexibly and even surpass the performance of the animal leather [3]. High-quality synthetic leather is used primarily in the automotive industry for interior trim. Unlike animal leather, synthetic leather offers water resistance, is easy to care for and neither needs to be waxed nor impregnated.

Did you know: even traditional luxury brands use coated leather or synthetic leather as particularly durable materials in their collections - Gucci and Louis Vuitton's famous monogram bags are made of coated faux leather, and Prada's Saffiano leather is a machine-grained and waxed leather.

Sustainability: Synthetic leather has its pros and cons. The extraction of the crude oil for production is intensive in terms of resources and the potential release of microplastics (albeit more present for textiles you wash often) is an issue. The environmental impact across categories like GHG emissions, water usage and chemicals used vary as much as the quality of the material: depending on the production country and site, raw materials used and material thickness, the environmental impact differs. However, scientific studies comparing standard materials used in the footwear, fashion and automotive space, show that, on average, the production of synthetic leather consumes significantly less resources than the production of animal leather [4].

Disposal: High-quality synthetic leather is characterized in particular by its durability. That being said, it also gives rise to problems when it comes to disposal: The material is very difficult to biodegrade, and recycling is not yet widespread in practice [6].

Deployment in the fashion industry: A large number of accessories, such as handbags and belts, are made from high-quality synthetic leather. Stella McCartney's luxury designer handbags, for example, are made from a blend of polyester (PL/PES) and polyurethane (PU). It is also widely used for the famous monogram handbags of luxury fashion houses like Louis Vuitton and Burberry (so-called coated canvas). Synthetic coated textiles are also widely used in footwear and fashion, for example for leather-like jackets or skirts.

Read more about animal leather and synthetic leather in our detailed article The 5 most popular myths about animal leather.

Peoples' ever-increasing interest in sustainability regarding fashion is also impacting their relationship with synthetic materials. Since synthetic leather is made from raw oil and its disposal is difficult, consumers are seeking other, vegan alternatives. As a result, several textile developers are trying to replace as much of the crude-oil-based raw materials as possible with plant fibers. Thus, a number of so-called plant-based leathers have emerged in recent years.

Management consulting and market research firm Infinium Global Research published a market report regarding the vegan leather market in February 2021. According to the report, the global vegan leather market is expected to grow at a compound annual growth rate (CAGR) of 48.1 percent during the forecast period from 2020 to 2026. The report includes profiles of companies such as Pineapple Anam Ltd, Desserto, Bolt Threads Inc and VEGEA SRL, among others [7].

Technology: Plant-based vegan leathers are leathers in which fruits, leaves or other plant-based components are industrially processed together with stabilizers in order for the final material to have the visual and tactile characteristics of animal leather.

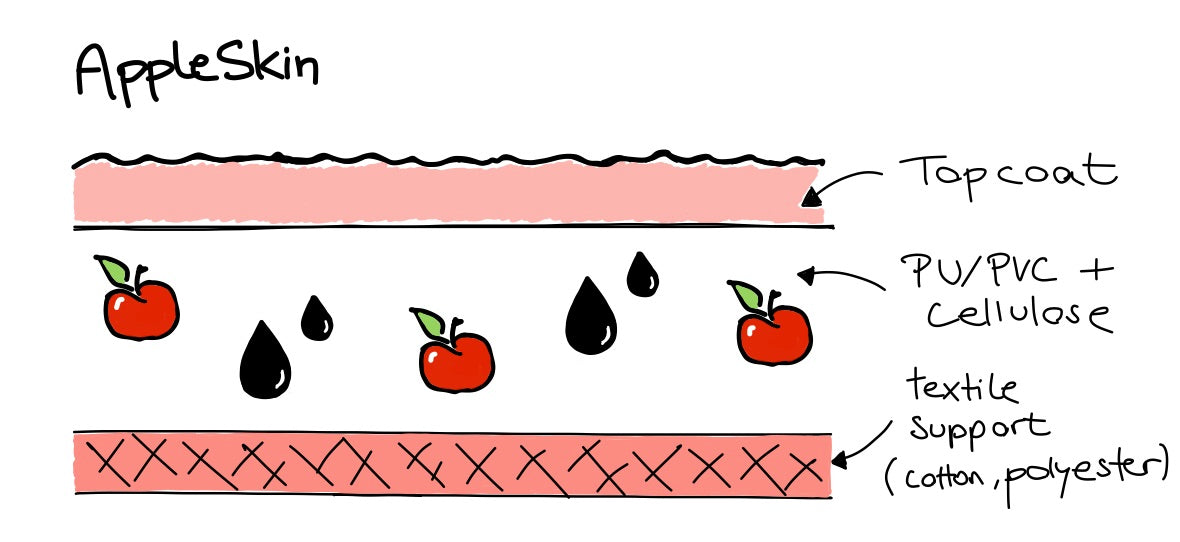

Similar to synthetic leather, they consist of a base material which is coated with one or multiple layers. This is where the plant-based raw component comes in: in the base material or coating, some of the synthetic raw materials are replaced by plant-based components. So, for example, some synthetic PVC/PU coating can be replaced by agricultural waste products [8]. Such examples are apple leather (AppleSkin, now called Uppeal, by Mabel Srl. and Leap by Beyond Leather), wine leather (VEGEA) or cactus leather (Desserto) as well as Ohoskin (made partially with sicilian oranges and cactus) and Oleatex (made with residues of the olive industry).

Figure 3: Material cross sections AppleSkin and Desserto.

Source: own illustration. [9]

In the case of Pinatex on the other hand, the pineapple leather from the manufacturer Ananas Anam, the base material is replaced: plant fibers from pineapple leaves (PALF = Pineapple Leaf Fibre) are coated with PLA (Polylactic Acid) and PU [10].

Figure 4: Material cross section Pinatex.

Source: own illustration. [11]

Performance: Hybrid leathers offer very similar basic visual and tactile characteristics to those of leather. Thereby, the synthetic components mostly serve as a stabilizer of the bio-based component, or to ensure that the qualitative requirements to which leather is subject can also be met.

Currently, there are hardly any scientifically based studies comparing the mechanical properties based on common parameters in materials science. Initial studies, however, indicate that performance depends in particular on the stability of the base material [12]. In developing our own samples, apple leather and cactus leather could be processed like synthetic leather. Unfortunately, pineapple leather was not so scratch-resistant in previous material tests that it would be suitable for the quality we require for designer handbags. However, for individual applications it works perfectly.

Sustainability: Even though the manufacturers of plant-plastic hybrids advertise the sustainability of their materials, there is little to no scientific data on the environmental impact to date. Desserto has published initial results of an LCA study [13] for its cactus leather, but the survey methodology is not yet publicly available. Therefore, the question of how materials such as apple leather, cactus leather or pineapple leather compare to animal or synthetic leather cannot be answered sufficiently.

One advantage of the hybrid material is certainly that some of the fossil raw materials are replaced by agricultural waste. For example, the apple powder of the manufacturer Mabel Srl., used for apple leather, is made from waste from the fruit juice production industry. The fruit content of the apple leather is about 20-30 %, the remaining 70-80 % being PU, polyester, and cotton [14]. Desserto is made with 33% cactus and 67% PU in the coating and a 55% polyester / 45% cotton textile backing in its standard material. Meanwhile, most of those companies also offer the possibility to fashion brands to customize their material, meaning that the actual bio-content can differ from product to product.

In addition, these young companies often provide information on manufacturing locations and conditions in a more transparent manner than is common in the animal leather or synthetic material industry. Surprisingly, however, the base material in the standard version of the materials is often polyester or polyester-cotton blended fabric, even though the companies advertise that they do not use fossil raw materials.

Disposal: Since the plant-based materials are mixed with synthetic components, biodegradability is not a given. Recyclability has also not yet been addressed, but in principle mixed materials are even more difficult to recycle than pure synthetic materials.

Deployment in the fashion industry: So far, the materials have proven themselves for the use in the production of accessories and can be processed in the same way as synthetic leathers. The German company Nuuwai, for instance, produces bags from Apple Skin and Sylven New York uses the material to make high-quality shoes. Since 2021, Karl Lagerfeld creates items in collaboration with Amber Valetta, including handbags made with cactus leather. The same material form Desserto was also used by BMW for a show car and a special edition Hublot watchband. Pinatex for example, which has unique design features due to its special surface texture, was used for shoes in a collection of HUGO BOSS.

Technology: A new, very exciting material is MIRUM® from Natural Fiber Welding, a US biotech company specialized in natural rubber chemistry. What makes it special: Natural Fiber Welding is the first company to succeed in developing a 100 % bio-based and plastic-free vegan leather. Like the other materials, MIRUM® uses a base material - which currently consists of organic cotton, cotton or Tencel. However, for the first time, the coating as well as the curing processes are not synthetic but are made with 100 % natural inputs [15]. The process has been patented and promises to eliminate the use of fossil oil following the motto Plants not Plastic.

Figure 5: Material cross section of Mirum®.

Source: own illustration. [16]

Performance: The material performs like animal leather in terms of its visual and haptic properties. During manufacturing, it is a slightly stubborn material that needs special skills to work with. During the last years, the performance increased tremendously, achieving technical performance required by the automotive industry. There is even a first show car showing MIRUM® in a seating application, one of the hardest to achieve applications for leather-like materials.

Sustainability: The manufacturer states that the production of MIRUM® requires only a fraction of the CO2 emissions and energy of animal and synthetic leather production. Furthermore, no water is consumed in the production process. A first LCA study conducted by Natural Fiber Welding in 2022, showed promising results with a calculated carbon footprint of 2.1 kg [17]. That is around 90% less than animal leather. They are currently re-assessing their impact for their new production line.

MIRUM® consists of only natural raw materials such as natural rubber, plant based oils, natural pigments and minerals. The raw materials are partly waste materials from other industries. Natural Fiber Welding uses FSC certified rubber for their material and also initiated a project with Terra Genesis in 2023 to create a regenerative supply chain for latex (the basis for natural rubber) together with latex farmers in Thailand [18].

MIRUM® has a clear advantage over other vegan leathers as it is made only from natural ingredients. The first versions have already received USDA biobased certification. Biobased referring to the fact that only biogenic raw materials are used for the material instead of fossil fuels or other nonrenewable resources. Moreover, no PU coating and no synthetic adhesives or dyes are used in the production process. This also makes it possible for MIRUM® to be recycled or to go back to nature safely [19].

Disposal: MIRUM® is circular by design – The material was developed for the circular economy [20]. Natural Fiber Welding initiated the EndWell program to recycle off-cuts from MIRUM® into new products. Due to its natural origin, the material can alternatively biodegrade and return to nature, although it does not currently meed biodegradability according to some specific country standards, where a material is only considered biodegradable if it decomposes in under a year [21].

Deployment in the fashion industry: MIRUM® had several market launches in the last years in the footwear, apparel and leather goods space. We were the first worldwide to launch the handle bag BAILEY made with MIRUM® in 2022, for which we were awarded the PETA Vegan Fashion Award and the German Sustainability Award in Design. Other great designers like ASK Scandinavia, Burggraf Burggraf, Anita Dongre or vegan brand Sentient also launched handbags out of this game-changing material. In the footwear space, Unless Collective and Nooch created a completely biobased sneaker with MIRUM®. PANGAIA used it in a capsule collection for a vest and some small leather goods. BMW is an investor in Natural Fiber Welding and they recently announced their first BMW Vision Neue Klasse with MIRUM® seating and interior. Until now, the material is only available in neutral colors like black, brown and off-white. Since, unlike synthetic leathers or plant-synthetic hybrids, it is not dyed with chemical dyes, but the color is created by minerals and other natural inputs, further colors are in development.

Technology: Uncaged is a material created by the female-founded startup Uncaged Innovation. The material is a coated textile with a coating based on grain proteins. The biotech startup tested thousands of biomaterial combinations to obtain a material with the best performance characteristics. By utilizing grain proteins, they mimic the structural function of collagen in an animal hide. Besides grain, the raw materials include natural rubber, coffee cherry and plant-based lipids.

Performance: Uncaged is still under development. First handfeel tests in our manufactory showed that the material is very soft and an excellent material comparable to standard synthetic and animal leather materials. Official test results for typical mechanical performance are not yet publicly available, but also promising. They already showed their materials can be manufactured in a roll-to-roll production process.

Sustainability: Uncaged utilizes different plant-based components to mimic the characteristic of animal leather. The backing material as well as the coating is 100% biobased. Right now, the company applies a thin layer (0.01 mm) of topcoat, which is about 1% of the total material composition. This topcoat is partially synthetic (67% plant-based and 33% synthetic). The material is available in a range of colors that are derived from plants or minerals, including some pops of colors like a red from cherry coffee. The backer is usually an (organic) cotton. A LCA study was not yet conducted.

Uncaged was founded by Stephanie Downs and Dr. Xiaokun Wang. Stephanie is a long-experienced founder and animal advocate. She is an ethical vegan that has also founded a vegan food startup in the past and worked for the Material Innovation Initiative. We love a fellow vegan joining this space, who will surely use its technology for the good. Dr. Wang has a Ph.D. in Biomedical Engineering from Georgia Tech and worked at Johns Hopkins University. She has over 15 years of experience developing novel biomaterials for biomedical applications.

Disposal: The material is > 99% biobased. How the partially synthetic coating influences biodegradation, still has to be determined. Tests to recycle the material are also to be conducted in the future.

Deployment in the fashion industry: Uncaged is a promising material still under development. They plan to launch first products in 2024 with selected brand partners. In 2023, they secured funding of $2 million including funding from InMotion Ventures, Jaguar Land Rover’s investment arm, who supports them in developing the material further for automotive applications.

Technology: Treekind is a material by the female-founded startup Biophilica from UK. The material is a coated textile with a coating based on lignocellulose feedstocks from local urban parks and gardens, agricultural waste and a natural binder. Like MIRUM®, it is made of 100% natural inputs and completely plastic-free.

Performance: While the material is still under development, it already achieved good test results in performance parameters like flexibility, tensile strength or abrasion [22]. As it is currently rather compact, it is best used in boxy shaped designs.

Sustainability: Treekind offers excellent sustainability parameters. It is a completely biobased, plastic-free material. A first LCA study conducted by the Bangor University, shows that the material only emits 2.19 kg of CO2, which is ca. 90% less than animal leather, as well as ca. 0.1% of water compared to an average leather tanning process. The material is either undyed in different natural hues like brown, dark red or dark green or it can be dyed with natural pigments. The backer typically consists of an undyed cotton.

Disposal: Treekind is the only vegan leather that is certified home compostable [23]. According to Biophilica, it can also be recycled, although this was only tested on lab scale so far.

Deployment in the fashion industry: Treekind is a very exiting material that is still under development. Been London has created some first bags and small leather goods, which are not yet commercially available. The Swiss watch brand ID Genève sells watch bands made with Treekind for their watches Circular 1 and Circular S. This very watch was also lately worn by Leonardo DiCaprio [24].

Technology: NUVI is a German startup creating biobased, plastic-free materials from a biobased polymer (more information not publicly available), plant and mineral fillers and a flax backing. All raw materials are sourced within the EU. Although some of the companies’ materials look leather-like, they specialize in materials reflecting the unadulterated characteristics of nature. NUVI is still under development, but already showed their materials can be manufactured in a roll-to-roll production process. They use for example marble powder for their material MARMORA, which leads to a material that has the same fine sheen to it as a marble rock. What was once a hard rock leads to a soft and drapey material, which gives designers new creative possibilities.

Performance: NUVI is still under development, but already showed their materials can be manufactured in a roll-to-roll production process. The company states that their materials can be used for applications like leather goods, footwear, interior or automotive, depending on the specific material, and that it has performance parameters similar to animal leather.

Sustainability: NUVI is a completely biobased, plastic-free material. All raw materials are sourced within the EU and the materials are manufactured in Germany. The material is either undyed, showing the natural characteristics of the raw ingredients, or it can be dyed with natural pigments. The backer typically consists of an undyed flax. A LCA study was not yet conducted.

Disposal: NUVI is made from natural raw materials only, and thus should readily be biodegradable. An official biodegradability test is planned.

Deployment in the fashion industry: NUVI promises new exciting design possibilities. The material is not yet commercially available. We have created a first showcase bag made with their chalk and marble material for the Future Fabric Expo in January 2024.

In the following you can find a thorough comparison of the most talked about vegan leathers based on scientific research. Where scientific research is not yet available, we marked as no sufficient data available. For the evaluation of performance, we included company information as well as our own experiences with the materials.

Comparison of the most talked about vegan leathers (© Melina Bucher).

Sources:

[1] Meyer, M.; Dietrich, S.; Schulz, H.; Mondschein, A. (2021): Comparison of the Technical Performance of Leather, Artificial Leather, and Trendy Alternatives. In: Coatings, 11, 226. Retrieved on 01. February 2021, https://doi.org/10.3390/coatings11020226, p. 2.

[2] Kumar, S. & Kumar, Y. (2021): Economic Sustainability Analysis of Natural Leather Industry, And Its Alternative Advancements, Open Access Master's Report, Michigan Technological University. Retrieved on 01. February 2021, https://doi.org/10.37099/mtu.dc.etdr/1203, p. 43.

[3] Meyer et al., 2021, p. 2.

[4] Herva, M.; Álvarez, A.; Roca, E. (2011): Sustainable and safe design of footwear integrating ecological footprint and risk criteria. Journal of Hazardous Materials. 9, 192(3):1876-1881. https://doi.org/10.1016/j.jhazmat.2011.07.028, p. 1879.

Kering (2020a): Sustainability Progress Report 2017-2020. Retrieved on 26. October 2021, https://keringcorporate.dam.kering.com/m/242e491bd51cfae0/original/Kering- Sustainability-Progress-Report-2017-2020.pdf

Kering (2020b): Material Intensities. Retrieved on 26. October 2021, https://kering-group.opendatasoft.com/pages/material-intensities/

Gottfridsson, M.; Zhang, Y. (2015): Environmental impacts of shoe consumption, Combining product flow analysis with an LCA model for Sweden. Retrieved on 01. February 2021, https://odr.chalmers.se/server/api/core/bitstreams/3b4dba7d-a0aa-4f29-931f-0d07e78e02b7/content, p. 35.

[5] Environmental Impact of Animal Leather vs. Synthetic Leather. The higher the number, the more harmful is a material for the environment. (HIGG Co, 2021, Material Sustainability Index, https://portal.higg.org/).

[6] Studies have identified both fungi and bacteria that decompose PU. However, biodegradability strongly depends on the exact chemical composition of the PU material used.

Howard, G. (2002): Biodegradation of polyurethane: a review. Retrieved on 22. October 2021, https://doi.org/10.1016/S0964-8305(02)00051-3, p. 245.

Howard, G. (2012): Polyurethane Biodegradation. Retrieved on 22. October 2021, https://link.springer.com/chapter/10.1007/978-3-642-23789-8_14, p. 374-381.

[7] Infinium Global Research, 2021, https://www.infiniumglobalresearch.com/reports/global-vegan-leather-market

[8] Meyer et al., 2021, p. 3.

[9] Exemplary representation of the material cross-section of Appleskin and Desserto, based on Meyer et al., 2021, p. 5-6.

[10] Using the example of Piñatex® ORIGINAL Amazon Green, https://store.ananas-anam.com/collections/original/products/original-amazon-green

[11] Representation of the material cross-section of Pinatex, based on Meyer Meyer et al., 2021, p. 5-6.

[12] Meyer et al., 2021, p. 7.

[13] Life-cycle assessments (LCA): These studies evaluate the totality of all energy and material flows within the value chain and calculate various potential environmental impacts. CO2 emissions, water consumption and toxicity, for example, are measured and evaluated.

[14] AppleSkinTM, https://luxtralondon.com/pages/apple-skin

[15] N atural Fiber Welding (NFW), https://mirum.naturalfiberwelding.com

[16] Representation of the material cross-section of MIRUM®, based on https://mirum.naturalfiberwelding.com

[17] NFW, https://blog.nfw.earth/mirum-lca-carbon-footprint

[18] NFW, 2024, https://online.fliphtml5.com/hpmqh/ofct/#p=22

[19] NFW, https://blog.nfw.earth/mirum-lca-carbon-footprint

[20] The circular economy aims to reuse used materials. Ideally, product cycles are closed according to the cradle-to-cradle principle. See also Meyer, at al., 2021, p. 1.

[21] Natural Fiber Welding, https://mirum.naturalfiberwelding.com/faq?hsLang=en

[22] Biophilica (2024): Treekind. https://www.biophilica.co.uk/treekind

[23] Home Compostable according to ISO 14855-1 testing procedure; Biophilica, 2024, https://www.biophilica.co.uk/treekind

[24] Something about Rocks (2023): Leonardo DiCaprio invests in eco watch brand ID Genève. https://somethingaboutrocks.com/article/leonardo-dicaprio-invests-in-eco-watch-brand-id-geneve/